Welcome To Alajeer Global FZCO.

Fueling the Future, Powering Progress

We Prioritize Excellence

At Al Ajeer, our steadfast commitment to quality underpins our operations. We view excellence as the foundation of our oil and gas services, ensuring every delivery embodies reliability, safety, and client satisfaction.

Precision in Quality

From extraction to distribution, our uncompromising standards ensure precision across all facets of our oil and gas operations.

Unyielding Reliability

Beyond petroleum products, it’s the trust our clients invest in us. At Ajeer Global, our relentless commitment to excellence in oil and gas operations seeks to earn and sustain that confidence.

Our Products

Crude Oil

Our crude oil trading operations are built on enduring global partnerships with producers and refiners. We enable producers to strategically market and distribute their daily output while ensuring refiners receive a consistent, high-quality crude supply through advanced, data-driven logistics and market expertise.

Fuel Oil

We dynamically optimize fuel flows and blends to address evolving global demand patterns. Currently, approximately 47% of global fuel oil supply supports marine bunkering, 30% powers electricity generation, and the remainder serves as refinery feedstock. Our strategy focuses on precision-blending to meet specific market demands, with operations centered in key fuel hubs, Singapore and Dubai, ensuring efficient and targeted delivery.

Liquified Petroleum Gas

Al Ajeer Global FZCO is a trusted leader in supplying Liquefied Petroleum Gas (LPG), delivering versatile and sustainable energy solutions to global markets. Our LPG portfolio includes propane, butane, isobutane, and mixed LPG, tailored to meet diverse industrial, commercial, and residential needs.With a robust global network and advanced logistics, including a specialized fleet of four Very Large Gas Carriers (VLGCs) and eight small-to-medium refrigerated vessels, we ensure reliable, end-to-end delivery from key hubs in Singapore and Dubai. Supported by state-of-the-art infrastructure, such as modern terminals and storage facilities, we optimize supply chains to provide high-quality LPG efficiently and sustainably.Partner with Al Ajeer Global FZCO for innovative LPG solutions that power progress while prioritizing environmental responsibility and operational excellence.

Middle Distillates

We trade a comprehensive portfolio of mid-distillates, including jet fuel, diesel, and gas oil, tailored to global market demands. Our suppliers leverage strategically leased global storage facilities to blend fuels to precise local specifications. Through trusted chartering partners, we deploy a versatile fleet, including large tankers and floating storage units, to optimize arbitrage opportunities and ensure rapid, reliable supply for customers with constrained storage capacity.

Gasoline

Al Ajeer Global FZCO supplies high-quality gasoline that meets stringent international specifications, ensuring optimal engine performance and efficiency for automotive and industrial applications. Our gasoline products are refined to deliver consistent octane ratings, superior combustion characteristics, and reliable fuel economy across diverse operating conditions. We maintain strict quality control throughout our supply chain, from sourcing to delivery, guaranteeing that our customers receive premium-grade fuel that enhances engine longevity and reduces maintenance costs. With competitive pricing and dependable logistics, Al Ajeer Global FZCO serves as your trusted partner for all gasoline supply requirements in the regional market.

Naphtha

We strategically source premium naphtha from key Middle Eastern producers and deliver comprehensive supply solutions to our global clientele across Asian, European, and American markets. Our business philosophy centers on cultivating enduring strategic partnerships while maintaining agility to adapt to our clients’ evolving operational requirements and market dynamics. Through our diversified product portfolio, we leverage naphtha’s inherent substitutability characteristics to optimize value propositions and enhance supply chain flexibility. We continuously analyze market intelligence, tracking relative price movements and demand fluctuations within the petrochemical sector to ensure optimal positioning and competitive advantage for our stakeholders.

Bitumen

Bitumen is manufactured across multiple performance grades to address the precise technical requirements and operational specifications of diverse end-user industries. Product classifications are established through comprehensive physical testing protocols that evaluate critical performance parameters including safety compliance, chemical solubility characteristics, structural durability, and operational resilience across varying environmental conditions and mechanical stress applications.

Base Oil

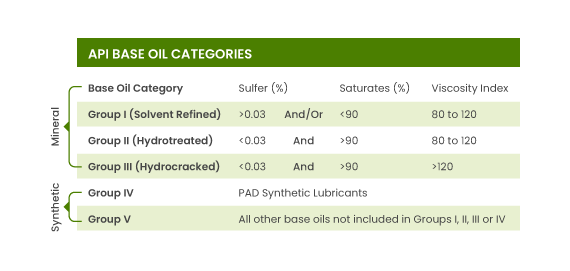

Group I

Group I base oils contain less than 90% saturates, over 0.03% sulfur, and have a viscosity index between 80–120. They are produced through solvent refining, a simpler process, making them the most affordable base oils. They operate best between 32°F and 150°F.

Group II

Group II base oils have over 90% saturates, less than 0.03% sulfur, and the same viscosity index range as Group I (80–120). Made by hydrocracking, they offer better oxidation resistance and a clearer color. Though more refined and slightly more expensive than Group I, they are widely used and similarly priced.

Group III

Group III base oils also contain over 90% saturates and under 0.03% sulfur, but with a higher viscosity index (120+). They are severely hydrocracked for higher purity and performance. Though derived from crude oil, they are sometimes classified as synthesized hydrocarbons and are becoming increasingly common.

Group IV

Group IV base oils are synthetic polyalphaolefins (PAOs), created through a chemical synthesis process. They offer excellent performance in extreme temperatures, both hot and cold, making them ideal for high-stress applications.

Group V

Group V base oils include all other base stocks not covered in Groups I–IV, such as esters, silicones, phosphate esters, polyalkylene glycols (PAGs), polyolesters, and biolubes. These are often blended with other groups to enhance lubricant performance. Esters, for example, improve high-temperature stability and provide superior detergency, extending oil life compared to standard PAOs.

Petrochemical

Petrochemicals are chemical products derived primarily from petroleum, though some can also be sourced from coal, natural gas, or renewable materials like corn and sugarcane. The two main classes are olefins (e.g., ethylene, propylene) and aromatics (e.g., benzene, toluene, xylenes).

Olefins are produced through fluid catalytic cracking in refineries or steam cracking of natural gas liquids.

Aromatics are created via catalytic reforming of naphtha.

These compounds are the building blocks for a wide range of products, including plastics, resins, fibers, solvents, detergents, adhesives, and more. Primary petrochemicals are classified into three groups: Olefins – Ethylene and propylene are key for plastics and industrial chemicals; butadiene is used in synthetic rubber. Aromatics – Benzene, toluene, and xylenes are used in dyes, detergents, polyurethanes, and synthetic fibers. Synthesis gas – A mix of carbon monoxide and hydrogen used to produce ammonia (for fertilizers) and methanol (as a solvent and intermediate).

Urea

For primary agricultural applications, urea is predominantly commercialized in solid formulations, available in both prilled and granulated configurations. Prilled products offer economic advantages through cost-effective manufacturing processes and established industrial production methodologies that preceded commercially viable granulation technologies. However, due to inherent particle size limitations required for optimal sphericity and reduced mechanical durability characteristics, prilled formulations typically demonstrate inferior performance in bulk storage, materials handling, and field application scenarios compared to granulated alternatives.Premium compound fertilizer formulations incorporating nitrogen co-granulated with complementary nutrients such as phosphates have maintained consistent commercial production since the modern fertilizer industry’s inception. Nevertheless, urea’s inherently low melting point and hygroscopic properties necessitated significant technological innovation to successfully adapt granulation processes for pure urea applications.Over 90% of global industrial urea production is allocated for nitrogen-release fertilizer applications. Urea maintains the highest nitrogen concentration among all commercially available solid nitrogenous fertilizers, resulting in optimized transportation economics per nitrogen nutrient unit. The standardized crop-nutrient specification (NPK rating) for urea is classified as 46-0-0.

Our Services

Distribution

In our commitment to providing top-notch customized solutions, distribution is a cornerstone of our service. We prioritize efficiency and reliability to ensure a seamless supply chain, delivering our high-quality products to your doorstep. Our distribution network is meticulously designed to meet the diverse needs of industries, businesses, and households, making us your trusted partner for dependable and timely delivery.

Storage Solution

Guaranteeing a robust and seamless supply chain, our state-of-the-art storage facilities underpin our dedication to delivering premium oil and gas products. Prioritizing safety, efficiency, and dependability, we invest in innovative storage solutions to meet the dynamic energy demands of industries, businesses, and households.

Quality Assurance

At Al Ajeer, our commitment to quality assurance is paramount. Rigorous testing, adherence to industry standards, and continuous improvement processes underscore our dedication to delivering products of the highest caliber. Your trust in our unwavering quality assurance practices is the foundation of our success.